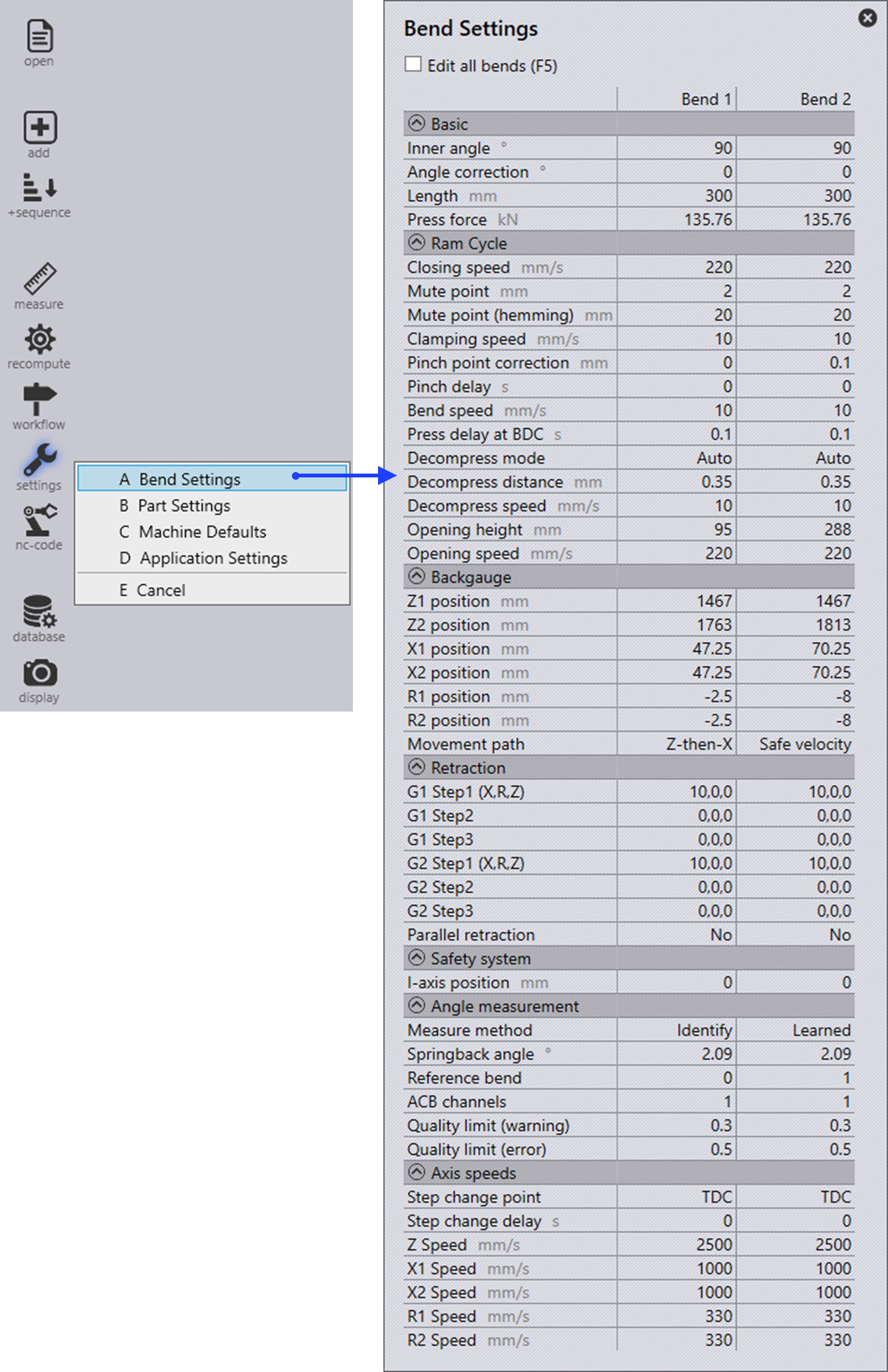

Bend Settings

Once a sheet metal bend is tooled using workflow menu, select settings icon and click Bend Settings or shortcut key A.

| Field | Description |

|---|---|

Opening angle |

The opening angle is displayed here. |

Length |

The bend length is displayed here. |

Press force |

The calculated press force is displayed here. |

| Field | Description |

|---|---|

Rapid down |

The speed of the beam up to the mute point. |

Mute point |

At the mute point, the max speed ("Rapid down") is automatically switched over to the reduced speed ("Clamping"). The mute point is above the top edge of the lower tool. "Mute distance 1" programmed sheet thickness = distance between the tip of the upper tool and the upper edge of the lower tool. |

Clamp |

The speed of the beam between the mute point and the clamping point. |

Clamping point correction |

Adjust the value to compensate for variations in sheet thickness. |

Waiting time at the clamping point |

The delay is mostly required by automated machines. During the waiting time, the beam will stop at the clamping point. Adjust the value e.gif a robot’s gripper reaches around the part. |

Press |

The speed of the beam between the clamping point and the machine’s lower dead point (LDP). |

Hold time at the LDP |

The beam will remain at the lower dead point (LDP) during the hold time. Due to the hold time, the material has enough time available during the bend to deform. Increase the value e.g when air bending thicker sheets or when coining. |

Auto-decompression |

Activated (standard): Select the value determined empirically by TRUMPF for the decompression path. |

Decompression path |

With the decompression path, the tension in the machine’s frame is released in a controlled fashion after a bend, as it is under maximum tension at the lower dead point (LDP). The decompression path moves the beam upwards at a slow speed. |

Decompression |

Speed of the beam along the decompression path (decompression). |

Opening |

The beam opening is the measure by which the beam moves upward after a bending operation. Positive value: Press beam is positioned above the mute point. Negative value: Press beam is positioned below the mute point. |

Rapid up |

Speed of the beam after the decompression path (decompression). |

Withdrawal direction |

Here you select in which direction the back gauge is to be withdrawn. |

Withdrawal |

Define withdrawal, value by which the gauge finger automatically moves away from the stop edge of the part once the part is clamped between the upper and lower tools (clamping point). |

| Field | Description |

|---|---|

Z1 position (Finger 1) |

Corresponds to the calculated position of the gauge finger Z1. |

Z2 position (Finger 2) |

Corresponds to the calculated position of the gauge finger Z2. |

X1 position (Finger 1) |

Corresponds to the calculated position of the gauge finger X1. |

X2 position (Finger 2) |

Corresponds to the calculated position of the gauge finger X2. |

R1 position (Finger 1) |

Corresponds to the calculated position of the gauge finger R1. |

R2 position (Finger 2) |

Corresponds to the calculated position of the gauge finger R2. |

Z |

Corresponds to backgauge Z1 and Z2 speed |

X1 Speed |

Corresponds to backgauge X1 speed. |

X2 Speed |

Corresponds to backgauge X2 speed. |

R1 Speed |

Corresponds to backgauge R1 speed. |

R2 Speed |

Corresponds to backgauge R2 speed. |